Keeping the Wheels of Industry Turning

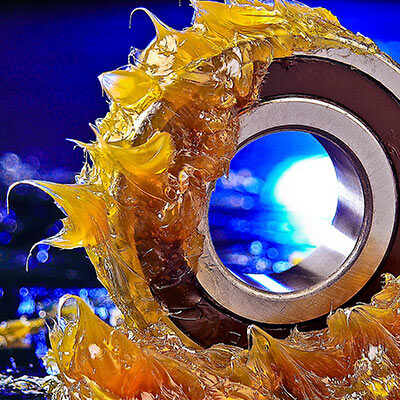

When we think about the industrial world and the complex machinery that powers it, we often overlook a critical component that keeps everything running smoothly: lubrication. Specialty and industrial lubrication play a pivotal role in ensuring the longevity, efficiency, and reliability of machinery across various sectors, from manufacturing and construction to aerospace and transportation. In this blog, we’ll delve into the world of specialty and industrial lubrication, exploring its significance, key applications, and the latest advancements in this field.

a. Understanding Specialty and Industrial Lubrication

What is Lubrication?

Lubrication is the process of reducing friction between moving parts by introducing a lubricant, typically a fluid or semi-fluid substance, into the contact area. This essential process serves several vital functions, including:

- Friction Reduction: Lubricants minimize the friction between machine components, reducing wear and tear, heat generation, and energy consumption.

- Heat Dissipation: They help dissipate heat generated during machinery operation, preventing overheating and potential damage.

- Contaminant Control: Lubricants form a protective barrier that prevents dust, dirt, and other contaminants from infiltrating machine components, ensuring smooth operation.

- Corrosion Prevention: Many lubricants contain additives that protect against corrosion and rust, prolonging the life of machinery.

Now, let’s dive deeper into the realm of specialty and industrial lubrication.

b. Applications of Specialty and Industrial Lubrication

1. Manufacturing and Machinery: In manufacturing, lubrication is the backbone of operations. Conveyors, assembly lines, hydraulic systems, and robotic equipment all rely on lubrication to maintain optimal performance. The choice of lubricant depends on factors like temperature, load, and speed, making specialty lubricants crucial.

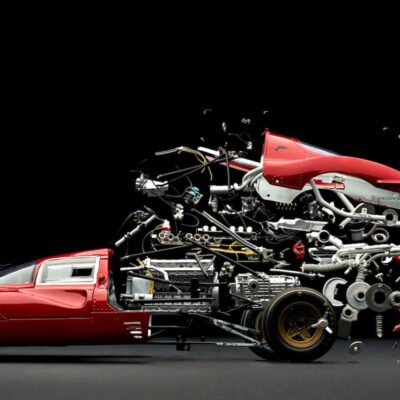

2. Automotive and Transportation: The automotive industry is highly dependent on lubrication. Engines, transmissions, and axles require specialized lubricants to operate efficiently and extend their lifespan. Lubricants also play a role in improving fuel efficiency.

3. Aerospace and Defense: In the aerospace sector, where precision and reliability are non-negotiable, specialty lubricants are indispensable. They ensure smooth operation in aircraft engines, landing gear, and a myriad of other components.

4. Construction and Mining: Heavy machinery used in construction and mining faces extreme conditions. Lubrication is vital for minimizing wear and tear, preventing downtime, and optimizing productivity.

5. Food and Beverage Industry: In food processing, lubricants must meet strict safety and health standards. Specialty food-grade lubricants are used to ensure the integrity of the final product and the safety of consumers.

c. Advancements in Specialty and Industrial Lubrication

The field of lubrication is continually evolving to meet the demands of modern industries. Some noteworthy advancements include:

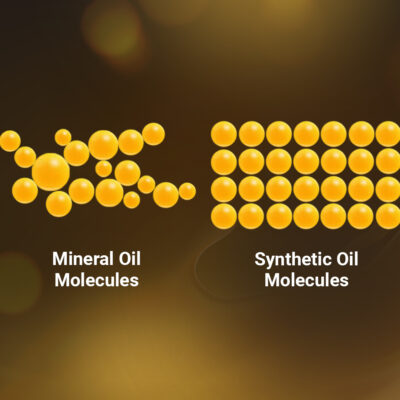

1. Nanotechnology: Nano-lubricants are engineered at the molecular level to reduce friction and wear, offering improved performance and longevity.

2. Bio-Based Lubricants: With sustainability in mind, bio-based lubricants made from renewable resources are gaining popularity, especially in environmentally sensitive applications.

3. Smart Lubrication Systems: IoT-enabled lubrication systems are revolutionizing maintenance practices. These systems provide real-time data on lubricant condition and machinery health, enabling predictive maintenance and reducing downtime.

4. High-Performance Synthetic Lubricants: Advances in synthetic lubricants have resulted in products that can withstand extreme temperatures and loads while delivering superior performance.

Conclusion

.

Specialty and industrial lubrication may not always be in the spotlight, but it’s undeniably one of the unsung heroes of the industrial world. Without proper lubrication, machinery would grind to a halt, leading to costly downtime and repairs. As industries continue to evolve, so too will the lubrication solutions that keep them running smoothly, efficiently, and sustainably. So, the next time you marvel at a complex piece of machinery, remember that behind the scenes, specialty and industrial lubrication are hard at work, ensuring everything runs like a well-oiled machine.

.